- Basic information

The metal detectors of the SC series (with single probe), SCTA (with tandem probe) register all ferrous and non-ferrous metals (from steel nut M4) in conveyed goods and are characterized by a high sensitivity.

That means: lowering costs and increasing productivity through optimal protection of sensitive machines.

- Function

The control unit feeds the probe with a high-frequency alternating voltage. An electromagnetic field is created perpendicular to the pole face of the probe, the lines of which penetrate the material to be conveyed. Only metal parts, including those enclosed in the conveyed material, change the curvature and damping of the field lines. The measurement signal obtained from this causes the output relay to report metal for 0.5 s. The size of the metal to which the detector should respond is continuously adjustable. The integrated automatic self-monitoring permanently checks whether the metal detector is still working properly. Is z. If, for example, the connection cable is interrupted or an electronic component in the control unit fails, a second output relay reports the pending fault. A built-in function control button simulates metal parts. It allows a quick and easy check of the functionality of the detector up to the connected control.

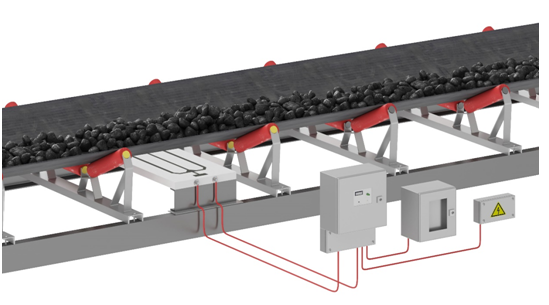

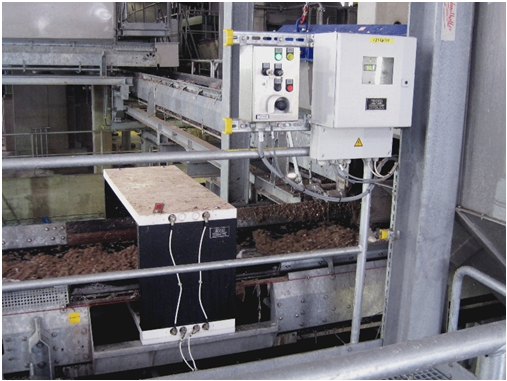

- Construction

The metal detector consists of a probe and a control unit. Both components are connected to one another by two connecting cables. The probe is compactly cast into a solid PE plate and is manufactured to match the width of the belt. The assembly on the conveyor belt is done easily and in a short time. Single and tandem probes are available. The lath-shaped single probe is attached under the belt. In contrast to this, the tandem probe consists of two probe plates, one of which is mounted under the belt and the other above the belt with the help of spacers. The tandem probe is particularly recommended for high dumping heights or high sensitivity requirements. The spacers of the tandem probe are manufactured according to the dump height. A single probe can also be modified to a tandem probe at a later date – a probe and two spacers simply have to be reordered and assembled.

- At a glance

- Solid and vibration-resistant design

- Simple, time-saving installation under or above the belt

- Displays ferrous and non-ferrous metals

- Separable and closed version of the probe

- Probe dimensions match the conveyor belt

- Special design with compensation of product effects, such as for: coke, aluminum foil, and other products with conductive segments

- Resistant materials for probe

- Integrated display for function control

- Automatic self-monitoring and function control button