- Basic information

The metal detectors of the SQ (single probe) and SQTA (tandem probe) series are protection and monitoring devices. They are used wherever disturbing and dangerous metallic foreign bodies of small to medium size (from steel nut M8) have to be indicated in the conveyed goods.

Our metal detectors avoid damage, prevent business interruptions and make it possible to save considerable repair costs.

- Function

The control unit generates a high-frequency alternating voltage. It reaches the probe via a connection cable. an alternating electromagnetic field builds up and penetrates the belt and the conveyed material. If a metal part gets into this field, distortions occur that lead to a trip. An amplifier registers this change and switches the output relay for 500 ms. The output relay has two potential-free changeover contacts that are available on an easily accessible terminal strip. The “metal message” signal can be further processed from the terminal strip, e.g. B. to stop the conveyor belt or to control a PLC. The integrated self-monitoring permanently checks whether the metal detector is still working properly. Is z. For example, if the connection cable to the probe is interrupted or if a circuit in the control unit fails, a second output relay switches over, the potential-free contact of which is also available on the terminal strip. A metal message can be simulated using the function control button. This enables a quick and easy check of the control connected to the metal detector. The commissioning of the EAB metal detectors SQ and SQTA is just as easy as the assembly: After setting the desired sensitivity, no further adjustment or adjustment work is necessary – the devices adjust themselves fully automatically to the existing operating conditions.

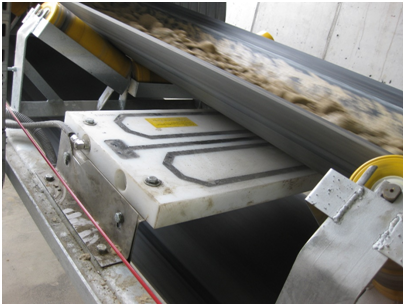

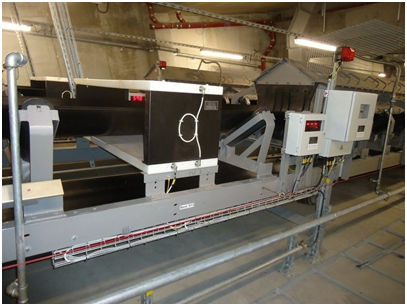

- Construction

The metal detector consists of a probe and a control unit. Both components are connected to one another by a connecting cable. The probe is compactly cast into a solid PE plate and is manufactured to match the width of the belt. The assembly on the conveyor belt is done easily and in a short time. Single and tandem probes are available. The lath-shaped single probe is attached under the belt. In contrast to this, the tandem probe consists of two probe plates, one of which is mounted under the belt and the other above the belt with the help of spacers. The tandem probe is particularly recommended for high dumping heights or high sensitivity requirements. The spacers of the tandem probe are manufactured according to the dump height. A single probe can also be modified to a tandem probe at a later date – a probe and two spacers simply have to be reordered and assembled.

- At a glance

- Self-balancing

- Particularly easy assembly

- No display of iron oxide or ore (special version), especially important for such conveying products as e.g .: magnetite, basalt, hematite and other up to 100% magnetizable materials

- Indicates FE and NF metals

- Automatic self-monitoring

- Can be used in the vicinity of frequency converters

- Minimum distance of the probe to motors and magnets only 1.5 meters clear width

- A solid and vibration-resistant probe and therefore resistant to weather, dirt and stone chips